A milling cutter is a rotating cutter with one or more cutter teeth for milling. When working, each cutter tooth intermittently cuts off the allowance of the workpiece. The milling cutter is mainly used to process planes, steps, grooves, formed surfaces and cut workpieces on the milling machine.

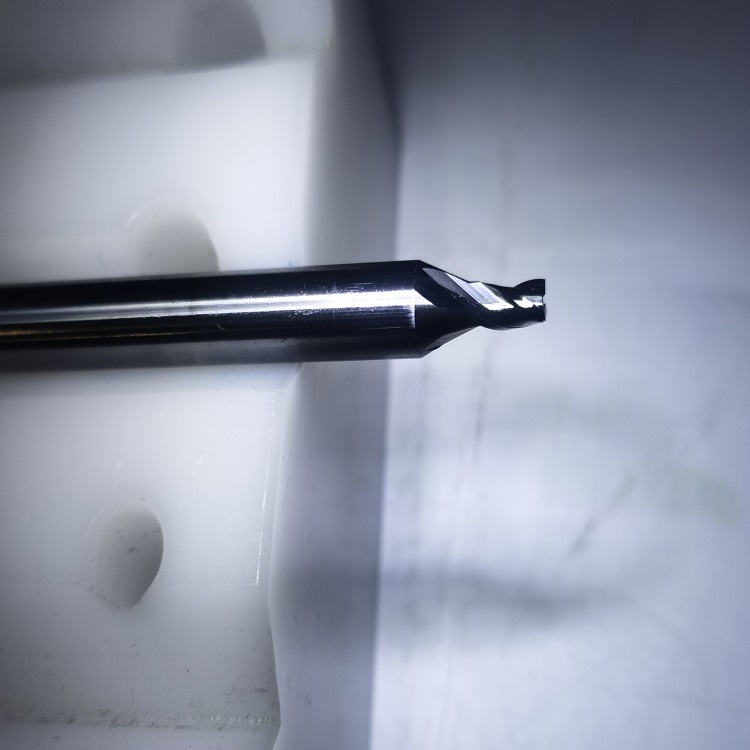

A milling cutter is a rotating cutter with one or more cutter teeth for milling. When working, each cutter tooth intermittently cuts off the allowance of the workpiece. Cemented carbide milling cutters are mainly used in CNC machining centers and cnc engraving machines. It can also be installed on an ordinary milling machine to process some hard and uncomplicated heat treatment materials.

The two-edge milling cutter is a keyway milling cutter, which belongs to the fixed size props, the accuracy of the keyway dimension is high, and the end face of the keyway milling cutter has no tip hole, so it can be fed directly down.

classification.

Milling cutter face milling cutter: also known as disc milling cutter, used for machining plane on vertical milling machine, end milling machine or gantry milling machine. There are cutter teeth on the end face and circumference, and there are also coarse teeth and fine teeth. Its structure can be divided into three types: integral type, tooth insert type and indexable type.

End milling cutter: used for machining grooves and stepped surfaces, etc., the cutter teeth are on the circumference and end face, and can not be fed along the axis when working. When there is an end tooth passing through the center on the end milling cutter, it can be fed axially.

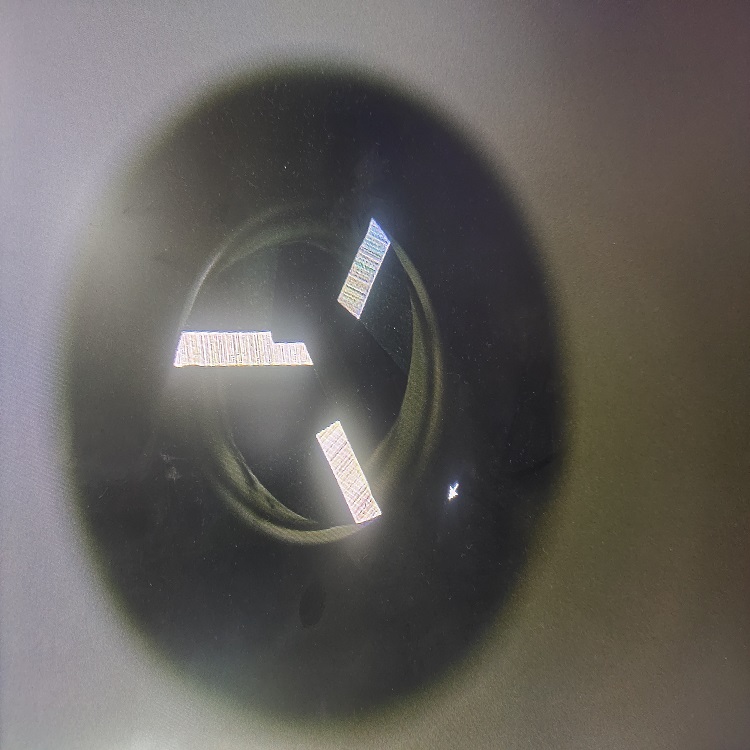

Three-edge milling cutter: used for machining all kinds of grooves and stepped surfaces, with cutter teeth on both sides and circumference.

Milling cutter angle milling cutter: used for milling grooves at a certain angle, there are single-angle and double-angle milling cutters.

Milling cutter saw blade milling cutter: used for machining deep grooves and cutting workpieces with more cutter teeth on the circumference. In order to reduce the friction during milling, there is a side deflection angle of 15 °to 1 °on both sides of the cutter tooth. In addition, there are keyway milling cutters, dovetail milling cutters, T-groove milling cutters and various shaped milling cutters.

T-shaped milling cutter: used for milling T-shaped grooves.